OUR PRODUCTS

Nimish Engineering is a valve manufacturer based in India that produces a wide range of industrial valves for various applications. The company has been in operation since 2001 and has gained a reputation for its quality products and excellent customer service.

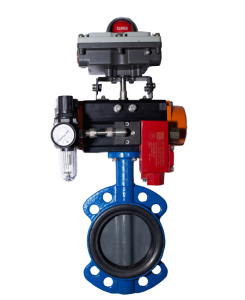

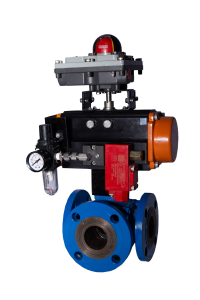

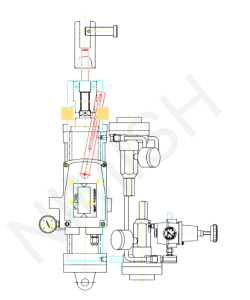

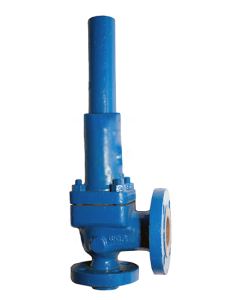

Nimish Engineering manufactures different types of valves, including ball valves, butterfly valves, globe valves, gate valves, check valves, and needle valves. These valves are made from various materials such as carbon steel, stainless steel, and cast iron, and are available in different sizes and pressure ratings.

The company uses advanced manufacturing techniques and modern machinery to ensure the highest level of precision and quality in its products. Nimish Engineering also provides customization options for its valves to meet specific customer requirements.

In addition to its manufacturing capabilities, Nimish Engineering also offers installation and maintenance services to ensure that its valves are properly installed and functioning efficiently. The company has a team of experienced technicians who provide on-site services to its customers.

Overall, Nimish Engineering is a reliable valve manufacturer that offers high-quality products and services to its customers. Its commitment to quality and customer satisfaction has made it a trusted name in the valve industry.

Professional Team

Great Support

Smart Work

CALL US OR FILL THE FORM

Fill all information details to consult with us to get services from us or call at +91 97021 37771

FAQ of customer

Our price strategy is to deliver exceptional value – without exception. : We supply superb quality, safe and durable valves with an outstanding technical and consultancy service, backup and spare parts.

We offer a high-value consultancy service with free no obligation on-site surveys.

Nimish Engineering will always be responsible for looking after your order. our goal to make your ordering experience easy, smooth and uncomplicated. So you can ask for a quote on the telephone (which we’ll follow up in writing) and you don’t need to quote parts’ numbers. Our aim is to assess your needs as quickly and efficiently as possible in order to quote you promptly

(1) we have received your deposit, and

(2) we have your final approval for production drawings. If our lead times do not work with your deadline, please send your requirements with your sale. In all cases we will try to accommodate our production plan to your needs.